Phone:

Introduction: DescriptionsModel ORMseries swing type granulator is a new special equipment for the granulating and material-spreading of belt type drier,which is designed on the basis of customers requirements and is in accordance with the currenly malpractices.We …

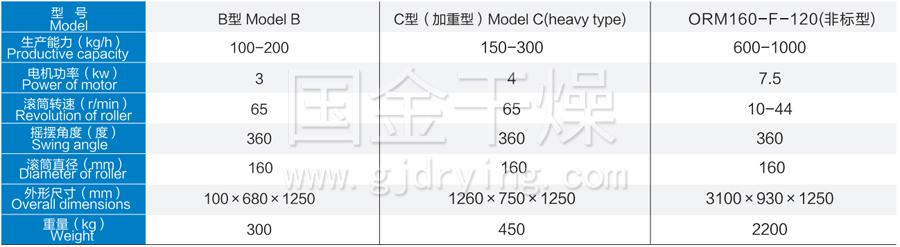

Model ORMseries swing type granulator is a new special equipment for the granulating and material-spreading of belt type drier,which is designed on the basis of customers requirements and is in accordance with the currenly malpractices.We also referred to the charcteristics of belt type drier,digested and absorbed its advanced technologies,and we also brought forth new ideas to the designs.This equipment has the features of a reasonable and simple structure,suflicient utility of energy, anadvanced granulating method,high efficiency and energy-saving and etc,thus it has multi-utilities of granulating,grinding and material distributing are suitable for granulating in pharmaceutical industry, chemical industry,foodstuff industry and etc.The most remarkable advantage of the equipment is that the granulating speed can be changed in a certain range and the material can be distributed uniformly.Thus it can keep the damp granule or dry granule in an identical size.The granules from this machine is uniformly and little in dust,convenience in operation,longlife in use,it can meet GMP requirements.

◆Well-distributed size,simple control:This machine is used to granulate the mixtrue of damp powder by forcing it through the screen mesh under the action of straight and reverse rotation of the by regulating.To regulate the tightness and looseness of the revolution of the rotary drum,the size and density of the material can be controlled in a certain degree.

◆Good sealibilty of the shaft rotation,no contamination to material:The main shatf is above the reducer and a tight shaft head seal structure is designed ensuring no oil penetrating out of the shaft,no material

penetrating,avoiding the material being contaminated by the grease, and meeting the requirements of AMP.

◆Electromagnetic speed-regulation,with speed-reducing and raising function:The machine changes the revolution of main shaft by adopting electromagnetical speed-regulation device,the faster the revolution is,the loose the granule will be;the slower the revolution is,the more solider the granule will be.By changing the revolution,the requirements for size can be met.Meanwhile through replacing the gears,the revolution of main shaft.

◆Beautiful in appearance,convenient in cleaning:The machine's enclosure adopts stainless steel strung plates,and it is clean and nonpoisonous.It is anti-corrusion.The part which needs to be cleaned is only the granulating chamber,that is mainly the screen mesh and hexagon retary drum.The rotary drum needn't to be disassembled.And the screen mesh is easy to be disassembled,it is very light and very convenient in cleaning.

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…

Most of China like to eat rice, and rice also accounts for a large proportion of my countrys grain cultivation. With the renewal of agricultu…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…