Phone:

Introduction: Working principle and features◆Pure water has the highest gasification speed under boiling condition.At normal pressure,pure water starts to boil at the temperature of1oo℃,under vacuum condition,as vapor pressure in the system is lower thanthat of …

◆Pure water has the highest gasification speed under boiling condition.

At normal pressure,pure water starts to boil at the temperature of1oo℃,under vacuum condition,as vapor pressure in the system is lower thanthat of material surface,boiling point of water is under1O℃,e.g.when surface is at0.O7MPa,water will boil at the temperature of70℃,the higher of vacuum pressure,the lower of boiling point.In the vacuum dryer,evaporated water can be removed quickly by the vacuum system, therefore,this dryer has larger drying capability all though it's under lower operation temperature.

◆Material is under static condition during operation of the equipment,which is benefit for keeping initial status of material, intermittent operation can adjust process conditions at any time.

◆On the top of VTD,dryer,heating system is arranged to tackle the problem of return of condensed water.To overcome the condensate water.To overcome the condensate return and drop problem effectively.

◆This equipment can be used for low temperature drying and solvent recovery,heat sources can be steam,hot water or conduction oil.

◆It is specially suitable for materials that is easily oxygenated during drying.

It is suitable for drying heat sensitive raw materials of pharmaceutical industry,chemical industry,foodstuff industry,electronic industry, Chinese herb medicine industry,etc.

◆It can get higher drying speed at lower temperature and the heat energy can be used fully.

◆It can dry at low temperature or can dry heat sensitive raw materials.

◆It can dry raw materials that contain solvent and the solvent needs to recover.

◆Before drying,it can carry out disinfectant treatment.during the period of drying,any impurity can not enter in it.

◆The dryer belongs to static vacuum dryer,the shape and volume of raw materials can not be damaged.

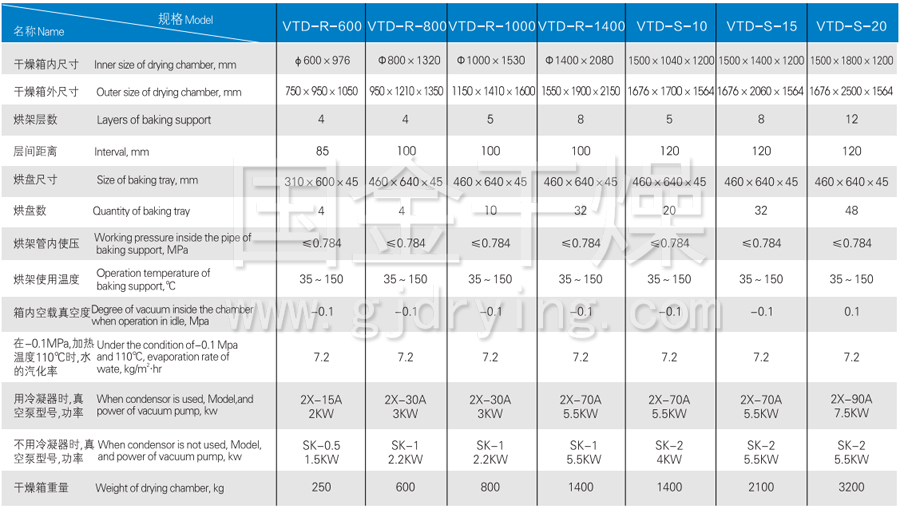

◆When order,please choose suitable vacuum dryer in accordance with the characteristics of raw materials to be dried such as,physical properties,primary moisture,temperature,vacuum degree,amount to be dried,drying time,etc.The vacuum dryer with same models three types i.e.,steam type,hot water type,heat conduction oil type.For example,in order to increase dry quantity,the quantity of layer of baking frame can be increased.Please put forward it to our factory.

◆The accessories used for vacuum drying system mentioned in

Operation Instruments can be provided and installed by our factory.Please explain it when order.

◆The factory can also provide design,manufacture and installation far special requirements of vacuum drier from customers.

◆The equipment of our factory carries out"guarantee of repair,replacement and refund of substandard product"and supplies all fittings for a long time.please put your mind at rest.

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…

Most of China like to eat rice, and rice also accounts for a large proportion of my countrys grain cultivation. With the renewal of agricultu…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…