Phone:

Introduction: DescriptionsSFD series roating flash dryer is developed by our company,and itstechinology is based on advanced techinology adored.The machineincludes many superiority,such as reasonable design, compactstuction,widly utilization,great productive capaci…

SFD series roating flash dryer is developed by our company,and itstechinology is based on advanced techinology adored.The machineincludes many superiority,such as reasonable design, compactstuction,widly utilization,great productive capacity ,good quality,higheffect and save energy,Drying,grinding and sieve are completed inone equipment in once time.It eliminates pollution and

the techinologyis reached international advance level.Flash drying machine has theoriginal bearing induction cooling (water cooling),oil pump design withconnection to send oil lubrication,cooling the bearing,sealperformance,on the spindle design USES a half ring, motor usingspeed regulation,smooth transmission,low noise,the service life is tentimes of similar products.

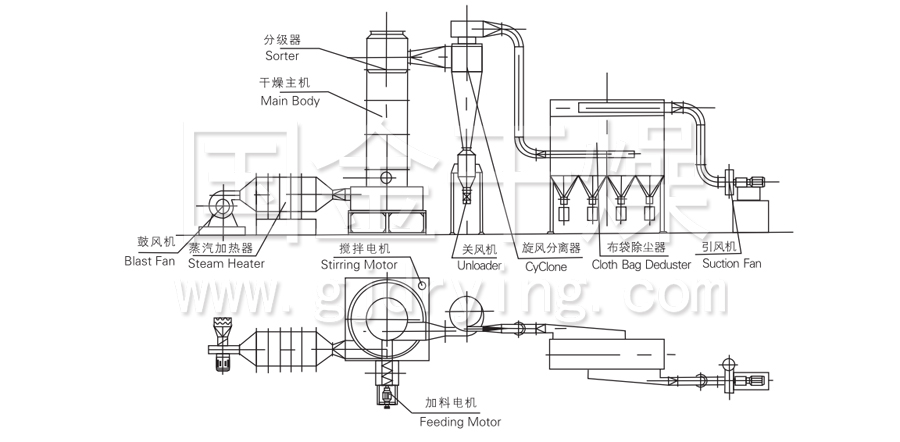

The hot air enters the bottom of the drier in tangent direction.Under the driving of the stirrer,a powerful rotating wind field is formed.The paste state materials enter into the drier through the screw charger.Under the powerful function of the stirring vanes at high-speed rotation,the materials are distributed under the function of strike,friction and shearing force.The block state mate-rials will soon be smashed and contact the hot air fully and the materials are heated and dried. The dried materials after the dewatering will g o up with the heatair flow.The step rings will stop and keep the big particles.Small particles will be discharged out of the drier from the ring center and will be restored by the whirl separator and dust remover.The not-fully-dried or big piece materials will be sent to the wall of the equipment by centrifugal force function and be smashed again after they fall down to the bottom.

◆This machine combines the whirl technology with the luidity,ejection and smashing step technologies.

◆The equipment is compact and small in size high in production efficiency and continuous in the production.It has realized that“a small equipment can perform the large production".

◆The drying capacity for this machine is big but its energy consumption is low.Its heat efficiency can go up to more than 70%.

◆The material stay time is very short.The quality of the final products is very good.The machine can be used for drying the heat sensitive materials.

◆For the negative pressure or the micro-negative pressureoperation, the machine is goog for its tightness and high in the efficiency so as to eliminate the environmental pollution.

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…

Most of China like to eat rice, and rice also accounts for a large proportion of my countrys grain cultivation. With the renewal of agricultu…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…