Phone:

Introduction: Principle of work◆With nitrogen as heat conduction medium,the equipment can dry materials in pharmaceutical,chemical,biochemical,biological and other technical fieldsmaterials containing organic solvents,as well as recover solvents,with safety,high e…

◆With nitrogen as heat conduction medium,the equipment can dry materials in pharmaceutical,chemical,biochemical,biological and other technical fields'materials containing organic solvents,as well as recover solvents,with safety,high efficiency and low energy consumption.

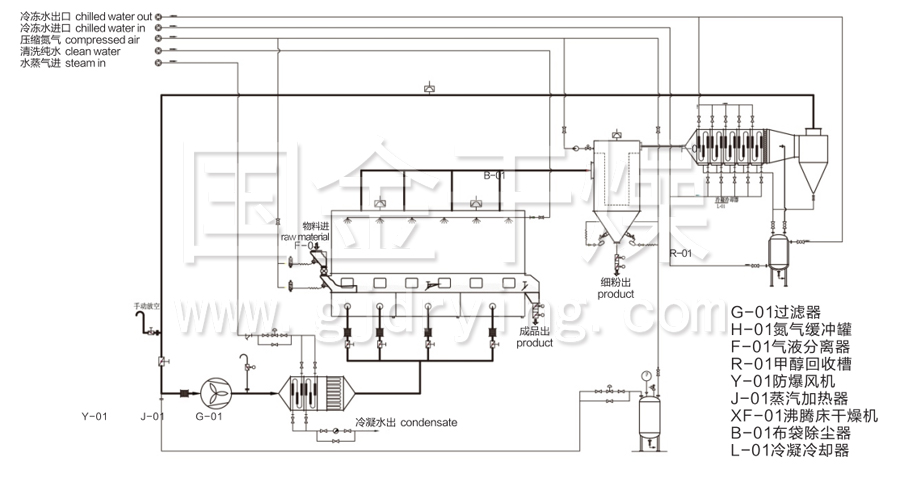

◆The air in dryer is heated by heat exchanger under the circulation of blower,and enters the fluidizing bed.Raw materials and hot air have full contact and heat exchange.After the solvent (methanol,acetone,the alcohol etc.in materials is evaporated,under circulating gas driving,fine powder will be collected by nitrogen back blowing bag dust collector,the evaporated vapour enters condenser and cool down by cold medium to recover solvent and separate gas. The separated gas is sent to heater again by fan,it works full cycle like this until all solvent is evaporated,separated and condensed from

material.

Features

Features

◆High efficiency:equipment is fully closed structure,no dead corner,air inlet and outlet are with high temperature and high efficiency filtration,dust removal efficiency is higher,disassembly and cleaning is easy.

It uses backflush technology after drying,dust removal is more thoroughly,cleaning frequency is lower,operation is simple,which effectively reduces labor intensity and to avoid contamination of product,production meets GMP requirements.

Equipment can run stably for a long time with a high degree of automation.It can not only dry,cool solvents,but also cool materials, drying efficiency is higher than rotary or harrow dryer,drying speed of 4-5 times quicker.At the same time after drying product quality is good and stable to create greater product value to users.

◆Environmental protection:the unit has achieved recycling of organic solvent during drying process,on the base in solving difficult drying and heavy pollution emission,it recover and re-use the solvent,at the same time,it gets zero emission to avoid exhaust pollution to environment and achieves practical effect for energy saving with emission reduction.

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…

Most of China like to eat rice, and rice also accounts for a large proportion of my countrys grain cultivation. With the renewal of agricultu…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…